Author: xiaoyu@brothermedical.com Publish Time: 2025-11-12 Origin: Site

At Brother Medical, we care about the same details as your users do — we believe that true comfort comes from precision that users can feel. For premium wheelchair users, the sense of luxury is defined not by price, but by how effortlessly each component responds in everyday use.

We replace common plastic or steel levers with customized 7000 series aluminum alloy brakes, offering a smoother, lighter, and more responsive feel. It turns every stop into a smooth motion.

Designed through 1:1 mold customization and crafted from high-strength aluminum, our armrest latch engages seamlessly and securely, ensuring both comfort and durability for daily operation.

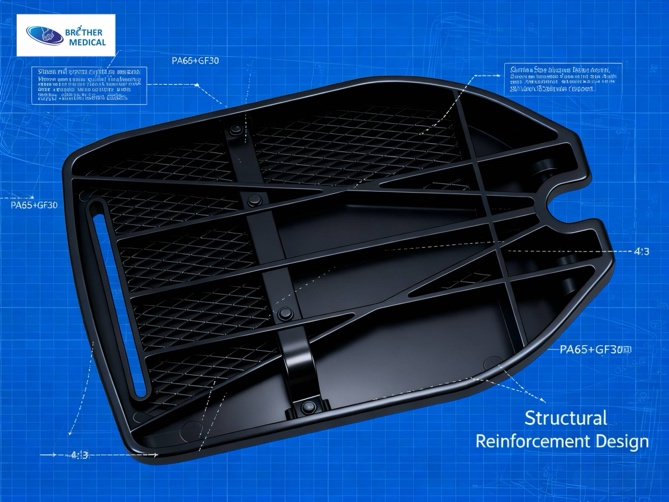

Our customized footrests are reinforced with designed rib structures, improving stability and resistance to deformation.

Each pedal surface features bespoke anti-slip patterns, combining functional strength with refined visual texture. It is durable under daily use, and elegant at first sight.

Each refined touchpoint transforms routine movement into a premium experience. In Brother Medical mobility engineering, the smallest details create the greatest difference and remarkability.

A perfectly tuned seat angle isn't just a matter of comfort — it's the result of 25 years of wheelchair design expertise and continuous refinement in ergonomic engineering.

At Brother Medical, every degree of tilt is intentional.

Our engineers analyze how seat depth, backrest inclination, and center of gravity affect propulsion, stability, and long-term posture. Through motion simulation and real-user testing, we fine-tune these dimensions to achieve a natural sitting balance that minimizes fatigue and maximizes maneuverability.

For this project, our goal was not only to replicate the client's original design 1:1, but to enhance it through engineering refinement — combining their creative vision with our 25 years of wheelchair design expertise.

Our engineering team optimized multiple elements of the frame for comfort, durability, and efficiency. One key breakthrough was the custom-engineered reinforced footrest, which resolved a long-standing durability issue in the client's previous model.

By redesigning the pedal support structure and introducing a textured anti-slip surface, we improved the product's structural strength and wear resistance by 42%, while maintaining its lightweight form and visual harmony.

The result: a smoother, stronger, and longer-lasting wheelchair — engineered for both performance and user experience.

Feature | Previous Design | Brother Medical Redesign | Improvement |

Footrest Durability | Standard welded plate | Reinforced rib structure | +42% strength |

Component Weight | 100% baseline | Optimized aluminum geometry | –15% weight |

Manufacturing Efficiency | Conventional tooling | Custom CNC mold | +20% efficiency |